Welding: Electron Beam, Laser, & Laser Hermetic Sealing

CERTIFICATIONS:

AMS 2680 • AMS 2681 • AWS D17.1 specification • NADCAP • AS9100D • ISO 9001:2015 • ISO 13485 certified • ITAR compliant

Electron Beam Welding can create joints that other processes cannot. Whether it is welding difficult material combinations together, or precisely placing welds within proximity of heat sensitive components, or simply creating the strongest possible welds from 0.005” to 3.0” penetration with a 20:1 depth-to-width ratio. Welding in high vacuum conditions result in high weld purity and strength. High energy density and precision beam placement provides for small heat affected areas. CNC controlled welders insure precise control and repeatability at feed rates from 1 to 200” per minute.

MATERIALS WELDED

- Titanium

- Inconel

- Aluminum

- Dissimilar Metal Combinations

Laser Welding is cost effective and fast. It is excellent for applications involving miniature components that require precise placement.

SPECIFICATIONS & FEATURES

- Precise Weld Penetration from .005” to 0.25”

- Pulsed Continuous Ware & Laser Stir welding up to 4 kw

- 3D (5axis) Welding available for prototyping & production runs

- Fiber Optic & Fixed Optics

- Dissimilar & Crack Sensitive Materials, & Magnetic Materials

- Manual, Semi-automated & Fully Automated Production

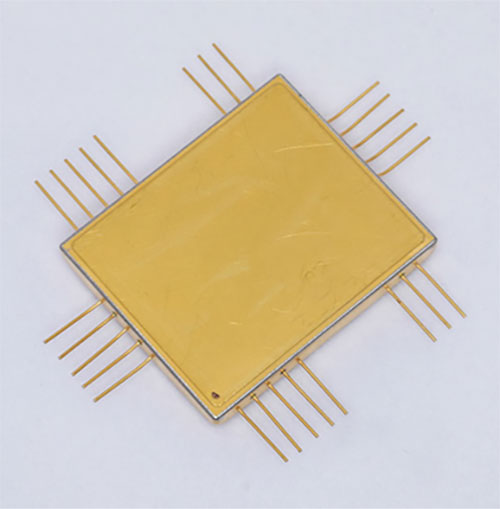

Laser Hermetic Sealing outperforms all other ways of sealing a component packaging. From the depths of the ocean to outer space, to inside the human body, laser hermetic sealing provides critical protection & design flexibility.

SPECIFICATIONS & FEATURES:

- Available for almost any package size or configuration

- Range of materials including Aluminum, Stainless Steel, Titanium, & Kovar

- Does not add mechanical weight or bulk to finished package

- Glovebox atmosphere with argon or nitrogen backfill

- Less than 10 PPM moisture & oxygen

- Gross & fine leak check down to 10 to the 10th power atm cc/sec

For Sales, Engineering and Product Design please contact:

Mark Foyil

601 Route 206, Suite 26-424

Hillsborough, NJ 08844

Ph: 908-431-1221

MFoyil@epictech.net

sales@epictech.net

© Copyright  • Site: D2P Web Design

• Site: D2P Web Design

• Call: 908-707-4085 or 908-431-1221

• Call: 908-707-4085 or 908-431-1221