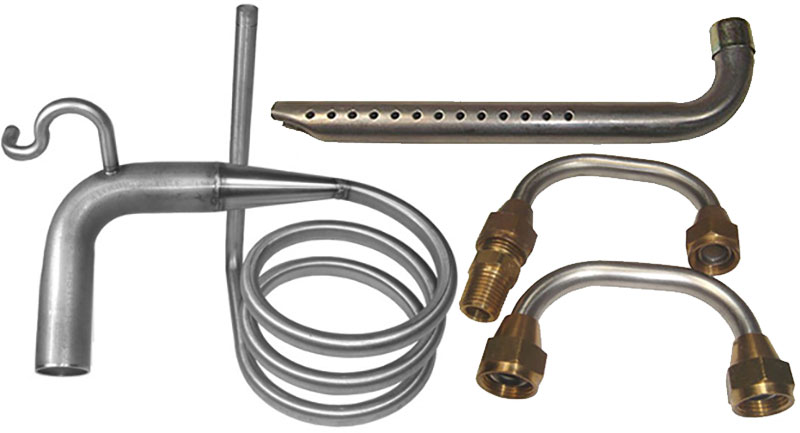

Metals: Tube Fabrication

ISO 9001:2015 Certified • PPAP

Our Tube Fabrication partner is a full-service metal tube fabricator specializing in automated-work cells. All bending operations are configured on an integrated CAD system, which links directly into their custom job shop software program. Various inventory control systems such as JIT, Kanban, and MRP are also used for production and cost efficiency.

CAPABILITIES

TUBE CUTOFF

TUBE COINING

MACHINING, THREADING, HOLES

|

TUBE END FORMING

TUBULAR ASSEMBLY

WELDING, GRINDING, POLISHING

|

TUBE BENDING

STAMPING/LASER

MATERIALS

|

LASER CUTTING

Minimum OD is .785”. Maximum OD is 7”. Maximum length is 120”.

PRODUCTS INCLUDE

Compressed Air Tubes, Tubing for Pneumatic Tools, Custom Refrigeration tubing, Heat Exchangers for the Commercial & Military Aircraft, Gas Tubes for Firearms Applications, Pitot Tubes and Handrails for Transit Cars.

For Sales, Engineering and Product Design please contact:

Mark Foyil

601 Route 206, Suite 26-424

Hillsborough, NJ 08844

Ph: 908-431-1221

MFoyil@epictech.net

sales@epictech.net

© Copyright  • Site: D2P Web Design

• Site: D2P Web Design

• Call: 908-707-4085 or 908-431-1221

• Call: 908-707-4085 or 908-431-1221