Plastics: Structural Foam Molding

ISO 9001:2015 Certified

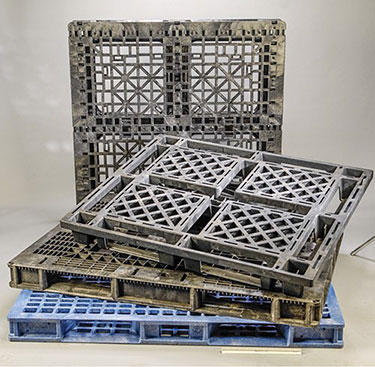

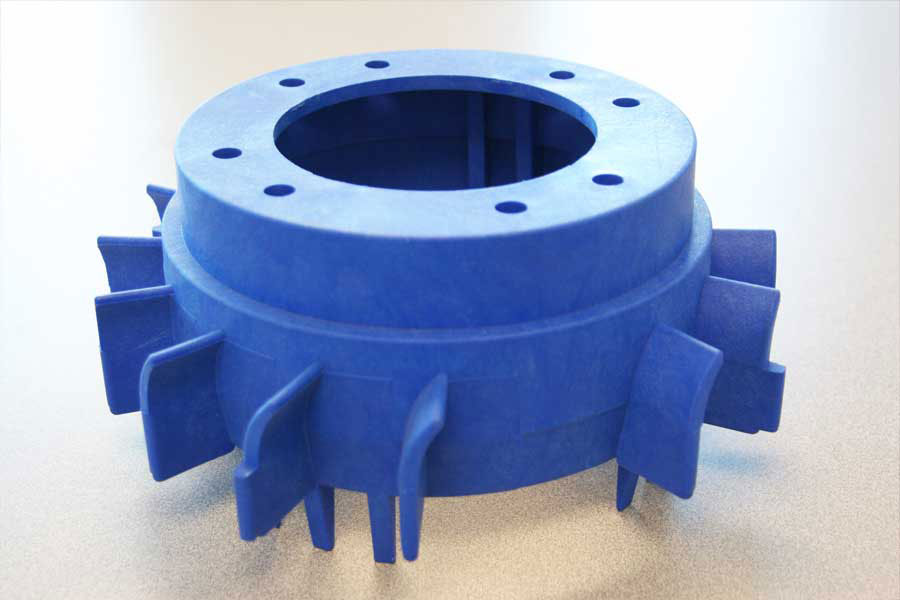

Our Structural Foam molder produces Thermoplastic, Injection Molded Structural Foam parts from standard and engineered materials. In-house secondary Finishing and Assembly capabilities are available.

STRUCTURAL FOAM BENEFITS INCLUDE

|

|

Structural foam molding is a process using low pressure injection molding with a foaming agent and/or inert gas insertion. The introduction of foaming agent into the melted plastic resin creates walls with a sandwich construction that has a solid skin on the outer layers and a foam core in the center.

This process creates molded parts which are lighter in weight, impact resistant, naturally buoyant, and exceptionally durable.

Mark Foyil

601 Route 206, Suite 26-424

Hillsborough, NJ 08844

Ph: 908-431-1221

MFoyil@epictech.net

sales@epictech.net

© Copyright  • Site: D2P Web Design

• Site: D2P Web Design

• Call: 908-707-4085 or 908-431-1221

• Call: 908-707-4085 or 908-431-1221